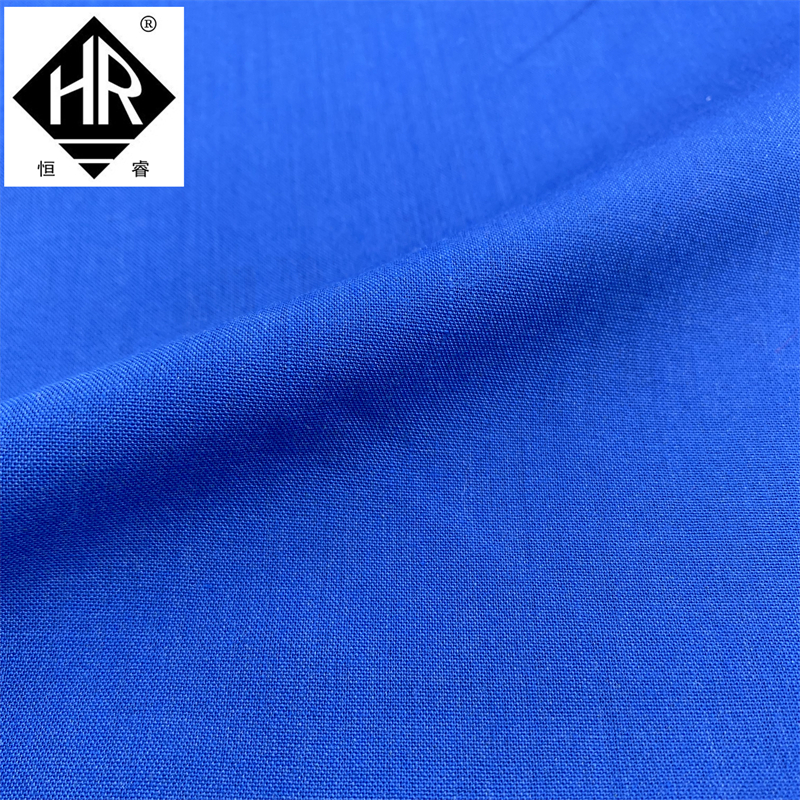

Special Flame Retardant Antistatic Aramid Lining Fabric

The fabric composition is: 38% meta-aramid, 30% flame retardant viscose, 30% flame retardant acrylic vinyl, 2% conductive wire.

This aramid fabric is a kind of lining fabric, it is specially designed for special work clothes in the oil and gas, protective clothing for oil pipeline workers, petrochemical protective clothing, chemical factory protective clothing, and other labor insurance garment.

This fabric is very breathable, lightweight, comfortable on direct skin contact, and dries quickly.

Our complete line of fabrics for oil, gas and petrochemical apparel provides protection and is soft and comfortable to wear. It can be used with our Aramid Fabric Oil and Gas Series 200gsm outer layer fabric to make a complete uniform.

The test showed that after 50 washes, the flame retardant protection performance was still qualified.

Flame Retardant

The fabric does not continue to burn away from the fire source, there is no smoldering, no melting or dripping. Permanently flame retardant. Washable.

Antistatic

Conductive filaments are evenly distributed on the fabric. The fabric has professional antistatic properties. In the oil work environment, there is a danger of static electricity, so this fabric can avoid this danger.

High temperature resistance

The fabric is resistant to high temperatures and has superior thermal protection.

High color fastness

The color fastness of the fabric to washing is 4-5, and the color fastness to light is 3-4. Vivid and bright colors.

The fine denier yarn is selected, and the fabric is delicate and high-grade.

Breathable

The fabric is comfortable and breathable, the fabric is light and thin, quick-drying, and weighs 125g/m2. The fabric is plain weave construction.

A variety of colors are available, and the fabric can be customized. Are you interested in this professional flame retardant and antistatic fabric? Please contact us for a free sample. Let us provide you with professional, suitable fabrics.

Features

· Inherently flame retardant

· High temperature resistance

· Heat Resistant

· Anti Static

· Ripstop

Standard

NFPA 2112, ISO11612, etc

Usage

Oil and gas, petrochemical, industrial protective clothing. Fireproof clothing

Test Data

| No. | Test items | Test Standard | Standard Requirement | Test Result | Conclusion | Remark | |||||

|

1 |

Flame retardant properties |

GB 8965.1-2020 5.1.2 |

Performance indicators | Warp | Weft |

Qualified |

Unwashed |

||||

| After flame time | ≤2s | 0.0s | 0.0s | ||||||||

| After glow time | ≤4s | 0.0s | 0.0s | ||||||||

| Damaged length | Do not burn through | Not burnt through | Not burnt through | ||||||||

| Melt, drip | None | None | None | ||||||||

| Ambient temperature(10-30)℃

Relative humidity(30-80)% |

Ambient temperature: 21℃

Relative humidity: 38% |

||||||||||

| Performance indicators | Warp | Weft |

Wash 50 times |

||||||||

| After flame time | ≤2s | 0.0s | 0.0s | ||||||||

| After glow time | ≤4s | 0.0s | 0.0s | ||||||||

| Damaged length | Do not burn through | Not burnt through | Not burnt through | ||||||||

| Melt, drip | None | None | None | ||||||||

| Ambient temperature(10-30)℃

Relative humidity(30-80)% |

Ambient temperature: 21℃

Relative humidity: 38% |

||||||||||

|

2 |

Thermal stability |

GB 8965.1-2020 5.1.2 |

≤10% |

Before washing | Length | 2.0% |

Qualified |

—— |

|||

| Width | 2.0% | ||||||||||

| After Washing | Length | 1.5% | |||||||||

| Width | 1.5% | ||||||||||

| Oven temperature: 180℃ | |||||||||||

| 3 | Formaldehyde content | GB 8965.1-2020 5.1.2 | ≤75mg/kg | Not detected (detection limit 20mg/kg) | Qualified | —— | |||||

| 4 | PH | GB 8965.1-2020 5.1.2 | 4.0-8.5 | 5.9 | Qualified | —— | |||||

| 5 | Peculiar smell | GB 8965.1-2020 5.1.2 | No peculiar smell | No peculiar smell | Qualified | —— | |||||

|

6 |

Point-to-point resistance |

GB12014-2019 4.1.2 | 1×105-1×1011Ω | 5.3×1010Ω |

Qualified |

—— |

|||||

| Ambient temperature:(20±5)℃

Relative humidity:(35±5)% |

Ambient temperature: 21℃

Relative humidity: 36% |

||||||||||

|

7 |

Charge surface density |

GB/T 12703.2-2009 |

≤7.0 uC/m2 |

Washing situation | Test Data |

Qualified |

—— |

||||

| Unwashed | 1.2 uC/m2 | ||||||||||

| Ambient temperature:(20±5)℃

Relative humidity:(35±5)% |

Ambient temperature: 21℃

Relative humidity: 36% |

||||||||||

|

8 |

Breaking strength |

GB/T 3923.1-2013 |

—— |

Warp | Weft |

—— |

—— |

||||

| 460N | 376N | ||||||||||

| Ambient temperature:(20±2)℃

Relative humidity:(65±4)% |

Ambient temperature: 21℃

Relative humidity: 63% |

||||||||||

|

9 |

Fabric dimensional change rate |

GB/T 8628-2013 GB/T 8629-2017 GB/T 8630-2013 |

—— |

Warp | Weft |

—— |

—— |

||||

| -1.0% | -0.6% | ||||||||||

| Ambient temperature:(20±2)℃

Relative humidity:(65±4)% |

Ambient temperature: 21℃

Relative humidity: 63% |

||||||||||

| 10 | Colorfastness to Soaping | GB/T 3921-2008 |

—— |

Discoloration

|

Level 4-5 |

—— |

—— |

||||

| Staining | Level 4-5 | ||||||||||

|

11 |

Colorfastness to Rubbing |

GB/T 3920-2008 |

—— |

Dry friction | Warp | Weft |

—— |

—— |

|||

| Staining | Level 4-5 | Level 4-5 | |||||||||

| Wet friction | Warp | Weft | |||||||||

| Staining | Level 4-5 | Level 4-5 | |||||||||

| Ambient temperature:(20±2)℃

Relative humidity:(65±4)% |

Ambient temperature: 21℃

Relative humidity: 63% |

||||||||||

|

12 |

Color fastness to perspiration |

GB/T 3922-2013 |

—— |

Color fastness to acid perspiration | Discoloration | Level 4-5 |

—— |

—— |

|||

| Staining | Level 4-5 | ||||||||||

| Color fastness to alkali perspiration | Discoloration | Level 4-5 | |||||||||

| Staining | Level 4-5 | ||||||||||

|

13 |

Color fastness to heat compression |

GB/T 6152-1997 |

—— |

Tidal pressure | Discoloration | Staining |

—— |

Pressurized temperature

(150±2)℃ |

|||

| Level 4-5 | Level 4-5 | ||||||||||

| Ambient temperature:(20±2)℃

Relative humidity:(65±2)% |

Ambient temperature: 21℃

Relative humidity: 64% |

||||||||||

Product Video

| Customize Service | Color, Weight, Dyeing method, Structure |

| Packing | 100meters/roll |

| Delivery Time | Stock Fabric: within 3 days. Customize Order: 30days. |